Double Layer Roofing Sheet Roll Forming Machine In Color Steel Africa Profile

Color Steel Africa Profile Double Layer Roofing Sheet Roll Forming Machine

Components

| No. | Name | Unit | Qty |

| 1 | Manual decoiler | set | 1 |

| 2 | Main forming machine | set | 1 |

| 3 | PLC control system | set | 1 |

| 4 | Hydraulic pump station | set | 1 |

| 5 | Post cut | set | 1 |

| 6 | Electric motor | set | 1 |

| 7 | Output table | set | 1 |

Technical process:

Automatic un-coiling →feeding guide →main roll forming → hydraulic cutting →outputting

Roll Forming Machine

Usage: In order to keep the product shape and precision, adopts

welded sheet structure, motor reducer drive, chain

transmission,roller was chromed which can keep the molding plate

surface smooth and not easy to be marked when it is being stamped.

Length of the main part: About 8500 1650 1500 mm (L*W*H)

Weight of main part: 6.5 tons

Voltage : 380 V 50 HZ 3 PHASE(As customer’s need)

Roller fixer : Middle plate

Frame : 350 H steel welded

Drive mode: Chain

Material of rollers: 45# steel, surface hard chromium plating.

Material of shafts: 45# steel

Diameter of shafts: φ 80 mm

Number of rollers : 13 rollers(Up layer)15 rollers(Down layer)

Cutting device

Feature : Ensure stability, precision and cutting speed

It is used to make the step , the glazed tile's final formed.

It adopts the hydraulic drive and automatic location to decide the

dimension and cut the target products. Function : Automatic cutting

controlled by PLC

Material of blades : Cr 12 quenched

Power supply : Hydraulic power

Components: It contains one set of blade, one hydraulic tank and

one cutter machine.

Hydraulic Station

It is controlled by gear wheel oil pump. After filling the

hydraulic oil into the hydraulic oil tank ,the pump drive the

cutter machine to begin the cutting job.

Hydraulic motor Power: 4 kw

Hydraulic oil: 46# hydraulic oil

Volume: 30 L

Components: The system includes a set of hydraulic tank , a set of

hydraulic oil pump, two hydraulic

Control System

1. Adopted PLC , transducer, touch panel to ensure high speed with

stability, precision and lifetime.

2. Voltage: 380V 50 HZ 3 PHASE (As customer’s need)

3. Language: English and Chinese

4. Automatic length measurement

5. Automatic quantity measurement

6. Length Tolerance: 3 m±1.5 mm

7. Length inaccuracy can be amended easily.

8. Unit of length: millimeter (switched on the control panel)

9. Computer operating panel: touching screen and button together.

Warranty

1. One year warranty, whole life technical support.

2. Installation & adjustment : We can take a video for the

customer and the customer can also come to our factory, we can

train customer how to install and adjust the machine.

3. Oversea service: the buyer should charge of visa, return ticket,

food and accommodation overseas and USD50/person/day salary.

Packing*Loading

1. One 40ft container for loading one set machine with manual

decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam

film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

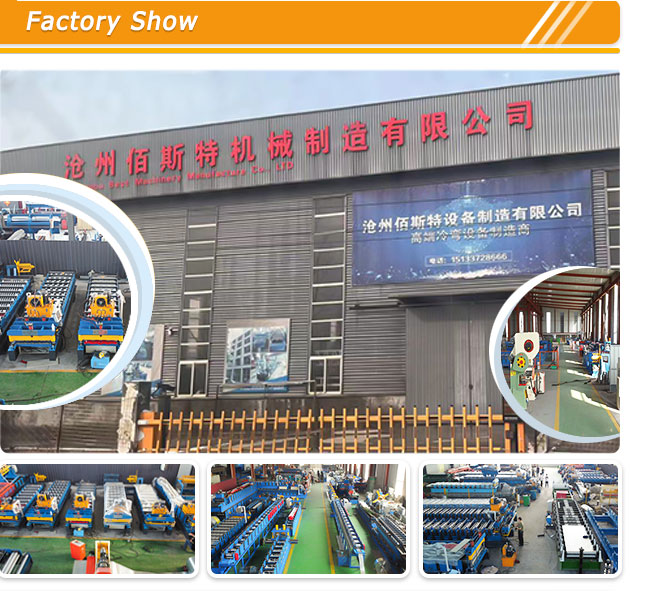

Cangzhou Best Machinery Co., Ltd

Cangzhou Best Machinery Co., Ltd set up in 2015, with great power in production and techniques, we are a leading manufacturer of roll forming machines in North of China.We have two workshops more than 4000 square meters, and have own processing machines and design engineer, so that can control machine production time and quality;Our factory is near Beijing or Tianjing, and in Cangzhou there is railway station, so it is convinent transport.Welcome to visit our factory anytime.

Our main products are CUSTOMIZED ROLL FORMING MACHINES, because

clients will use roll forming machines instead of bending machine

or pressing machines to save labor, and improve production, our

regular products are roof sheet roll forming machine, roof tile

roll forming machine, CZ roll forming machine, floor decking roll

forming machine, highway guardrail roll forming machine, cable tray

roll forming machine, stud and track roll forming machine, door

roll forming machine, slitting and cut to length, sandwich panel

machine and so on.

We have advanced production equipment and our engineering personnel

and technicians have extensive experience in designing, developing,

and manufacturing machineries. They pay close attention to and keep

up with the developing trend of technologies and use new

technologies in manufacturing machinery, to keep them competitive.

Our products feature high efficiency, high flexibility and low

cost.

"Customers are the first, success comes from development" is our

principle. We bear this in mind during the whole process from

design and development of product to after-sales services. We will

design and manufacture machinery strictly in accordance with your

requirements.

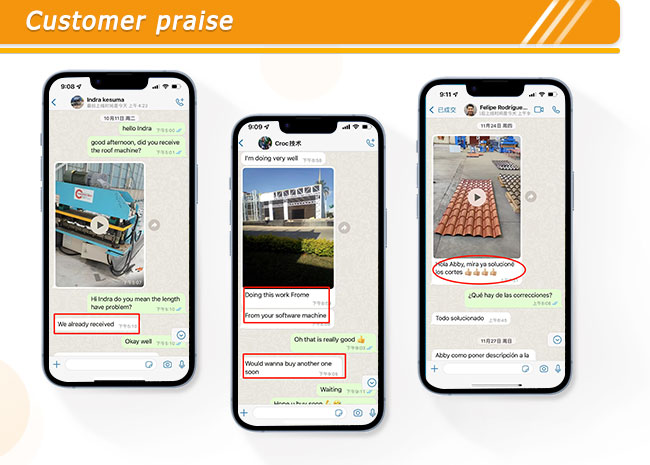

With good after-sales service network, we can provide support

covering the whole process of purchasing, which help you get

perfect machinery. We'll solve all the problems you have while

using the machines and we'll provide considerate services.

Our machines have been sold to North America, like US, Canada, South America, Nicaragua, Peru, Brazil, Bolivia, Uruaguy, Argentina, Europe, like Greece, Middle east, like Saudi Arab, Dubai, Iran, Iraq, Africa, Egypt, Ghana, Nigeria, Ethiopia, Malawi, Kenya, Tanzania, Zambia, Zimbabwe, South Africa, Australia, New Calidonia, Asia, India, Thailand, Philippines, Indonesia, Papua New Guinea,

Bangladesh, Pakistan, Turkmenistan, Malaysia, Vietnam, Mongolia, helping us enter the

international market.

Excellent service and high technology assist you to create a bright

future.

To make sure machine quality, we applied CE certificate and SGS

certificate and so on.

Our roll froming machine exported all over the world and win good repution,clients give good feedback,we have been exported to more than 120 countries and regions in the world, including: Germany, Japan, Italy, Russia, Japan, South Korea, Turkey, Brazil , India, the United Arab Emirates, Saudi Arabia and other countries, the products are subject to a great welcome and praise. INDIA, AFRICA, SOUTH AMERICA.

WE WILL YOUR BEST SUPPLIER IN CHINA,WELCOME TO CONTACT US.