Long Span Steel Material Building Roofing Sheet Roll Forming Machine CE / BV / SGS

Product Description

K-Span system mobile roll forming machines are capable of constructing arch buildings and roofs on site, with spans ranging from as narrow as 4m to as wide as 40m. There is no limitation on the length of the building or roof that can be produced.

K-Span system arch roofs can be installed on masonry brick, concrete or steel structures, eliminating the need for a conventional roof support structure.

K-Span system arch buildings and roofs can be adapted to fit existing infrastructure or be considered as a standalone solution for new projects.

Main technical specification:

| Size | 9,000mm×2,250mm×2,300mm |

| Total Weight | About 10,000KG |

| Cutting Material | Cr12Mov, Heat treatment |

| Cutting Type | Hydraulic/Mechanical controlling cutting |

| Total Motor Power | 18.5KW |

| Forming Power | 7.5KW |

| Bending Power | 4.0KW |

| Cutting Power | 4.0KW |

| Conical Power | 1.5KW |

| Material of Rollers | 45#steel, quenched HRC 58-62 |

| Material of Shafts | 45#steel, adjusted |

| Step of Rollers | 13 |

| Max Span | ≤15m |

| Width of the Panel | Feeding width: 914mm , Finished width: 610mm |

| The Depth of the Groove | 86mm |

| Operating Factor of the Panel | 0.82 |

| Thickness of the Panel | 0.8-1.5mm |

| Working Speed | Straight Sheet: 15mm/min, Arch Sheet: 13m/min , Seaming: 6m/min |

| Electric Standard | 380V/50HZ/3PHASES or according to your requirement |

| Controlling System | PLC(Omron,Japan) |

Product Size

| TYPE | Feeding Width (mm) | Finished Width(mm) | Groove Depth(mm) | Coil Thickness (mm) | MaxSpan | Use ratio |

| CS-600-305 | 600 | 305 | 109 | 0.8-1.5 | ≤24m | 51% |

| CS-914-400 | 914 | 400 | 210 | 0.8-1.5 | ≤40m | 43.80% |

| CS-914-610 | 914 | 610 | 203 | 0.8-1.5 | ≤38m | 66.70% |

| CS-914-650 | 914 | 650 | 181 | 0.8-1.5 | ≤28m | 71.10% |

| CS-914-700 | 914 | 700 | 123 | 0.8-1.5 | ≤24m | 76.60% |

| CS-914-750 | 914 | 750 | 86 | 0.8-1.5 | ≤15m | 82% |

| CS-1000-400 | 1000 | 400 | 253 | 0.8-1.5 | ≤40m | 40% |

| CS-1000-550 | 1000 | 550 | 187.5 | 0.8-1.5 | ≤30m | 55% |

| CS-1000-610 | 1000 | 610 | 243 | 0.8-1.5 | ≤39m | 61% |

| CS-1000-680 | 1000 | 680 | 223 | 0.8-1.5 | ≤32m | 68% |

| CS-1000-700 | 1000 | 700 | 175 | 0.8-1.5 | ≤28m | 70% |

| CS-1000-750 | 1000 | 750 | 138 | 0.8-1.5 | ≤25m | 75% |

| CS-1000-800 | 1000 | 800 | 114 | 0.8-1.5 | ≤14m | 80% |

| CS-1220-800 | 1220 | 800 | 300 | 0.8-1.5 | ≤42m | 65.50% |

| CS-1250-800 | 1250 | 800 | 320 | 0.8-1.5 | ≤42m | 64% |

Advantage of our Roll Forming Machine Building Sheet Arch Machine:

HIGH SPEED OF CONSTRUCTION

With our MBM Mobile Factory, a 1000-square meter structure can be built in 24 hours. Using the high speed of fabrication and seaming of panels,a crew of 10 to 12 workers can fabricate and erect nearly 100 arched panels in one day.

LOW COST

Due to the above reason, the cost of construction of a MBM Building

is less than that of conventional and prefabricated buildings.

ON-SITE MANUFACTURING

The Mobile Factory is taken directly to the construction site and

the building is fabricated completely on-site. No costs of shipping

of building components from a fabrication shop are incurred.

MOBILITY AND ACCESS TO REMOTE AREAS

Our trailer-mounted MBM Factories can be easily towed by and

ordinary vehicle to any remote part of the country and put into

operation the moment it arrives at the site without any delay

whatsoever.

NO STRUCTURAL COLUMNS, BEAMS OR TRUSSES REQUIRED

The arches are designed to be totally self-supporting and do not

require any support structure such as is needed in standard steel

frame buildings.

SAVINGS IN MANPOWER

Our crew of approximately 10 to 15 trained men can erect a 1000

square meter building in a single day. You can build your buildings

in either steel or aluminum, prepainted in an unlimited range of

colors. We also stock most of our coils and immediately ship with

our unit to the site.

Color metal glazed tile roofing sheet making machine with 3D effect is delivered by nude with oil putting. It will be fixed in the container tight by steel wire.

Our Services

Cangzhou BEST cold rolling forming machines we give the following before and after sale service:

1. Once we receive your drawing, we will give you some feedback according to our expereince.If there is some mistake in the drawing, we can point it out at the first time.

2. In the production, you can watch the whole prduction by camer if you like.

3. we give two year totally free after sale service and whole life tech support. For indian customer we give whole life free tech and engineering and free installation as we have warehouse and engineer there. Please know a little more about our factroy.

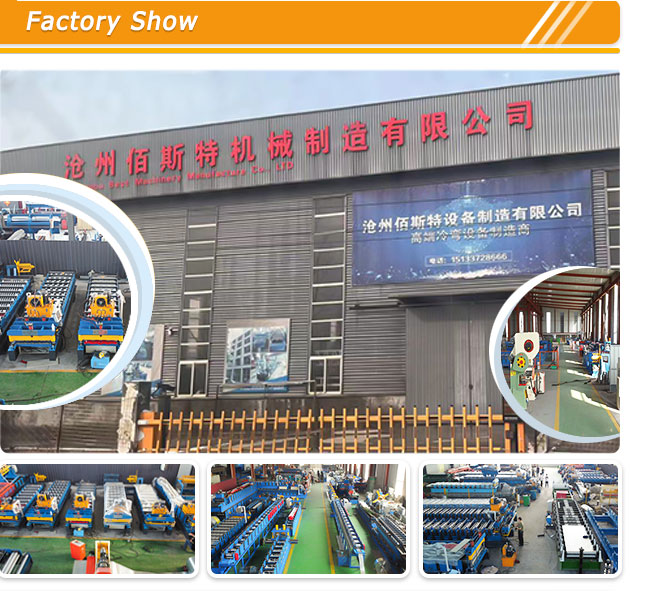

Cangzhou Best Machinery Co., Ltd

Cangzhou Best Machinery Co., Ltd set up in 2015, with great power in production and techniques, we are a leading manufacturer of roll forming machines in North of China.We have two workshops more than 4000 square meters, and have own processing machines and design engineer, so that can control machine production time and quality;Our factory is near Beijing or Tianjing, and in Cangzhou there is railway station, so it is convinent transport.Welcome to visit our factory anytime.

Our main products are CUSTOMIZED ROLL FORMING MACHINES, because

clients will use roll forming machines instead of bending machine

or pressing machines to save labor, and improve production, our

regular products are roof sheet roll forming machine, roof tile

roll forming machine, CZ roll forming machine, floor decking roll

forming machine, highway guardrail roll forming machine, cable tray

roll forming machine, stud and track roll forming machine, door

roll forming machine, slitting and cut to length, sandwich panel

machine and so on.

We have advanced production equipment and our engineering personnel

and technicians have extensive experience in designing, developing,

and manufacturing machineries. They pay close attention to and keep

up with the developing trend of technologies and use new

technologies in manufacturing machinery, to keep them competitive.

Our products feature high efficiency, high flexibility and low

cost.

"Customers are the first, success comes from development" is our

principle. We bear this in mind during the whole process from

design and development of product to after-sales services. We will

design and manufacture machinery strictly in accordance with your

requirements.

With good after-sales service network, we can provide support

covering the whole process of purchasing, which help you get

perfect machinery. We'll solve all the problems you have while

using the machines and we'll provide considerate services.

Our machines have been sold to North America, like US, Canada, South America, Nicaragua, Peru, Brazil, Bolivia, Uruaguy, Argentina, Europe, like Greece, Middle east, like Saudi Arab, Dubai, Iran, Iraq, Africa, Egypt, Ghana, Nigeria, Ethiopia, Malawi, Kenya, Tanzania, Zambia, Zimbabwe, South Africa, Australia, New Calidonia, Asia, India, Thailand, Philippines, Indonesia, Papua New Guinea,

Bangladesh, Pakistan, Turkmenistan, Malaysia, Vietnam, Mongolia, helping us enter the

international market.

Excellent service and high technology assist you to create a bright

future.

To make sure machine quality, we applied CE certificate and SGS

certificate and so on.

Our roll froming machine exported all over the world and win good repution,clients give good feedback,we have been exported to more than 120 countries and regions in the world, including: Germany, Japan, Italy, Russia, Japan, South Korea, Turkey, Brazil , India, the United Arab Emirates, Saudi Arabia and other countries, the products are subject to a great welcome and praise. INDIA, AFRICA, SOUTH AMERICA.

WE WILL YOUR BEST SUPPLIER IN CHINA,WELCOME TO CONTACT US.