80-300 C U Purlin Cold Metal Roll Forming Machine Steel Frame 8-12m/Min

Steel Frame 80-300 C U Purlin Cold Metal Roll Forming Machine Lowest Price

Main Parameters:

| 1 | Coil width | 100-400mm |

| 2 | Cover width | 80-300mm |

| 3 | Coil sheet thickness | 1.5--3.0mm |

| 4 | Material of frame | 400H steel |

| 5 | Diameter of shaft (solid shaft) | (high grade) 45# Steel |

| 6 | Diameter of shaft (solid shaft) | 80mm |

| 7 | Treatment of roller | quenched and tempered treatment, hard chromized coated 0.05-0.07mm |

| 8 | Thickness of middle plate | 20mm |

| 9 | Forming station | 15 stations |

| 10 | Drive type of roll forming machine | drive by chain(0.8 inch) |

| 11 | Power of main motor | 11KW |

| 12 | Motor power of hydraulic station | 4KW |

| 13 | Oil pump of hydraulic station | No.46 gear oil pump (high grade) |

| 14 | Forming speed | about 8-10 m/min |

| 15 | Voltage | 380V/50Hz/3phase |

| 16 | Hydraulic cutting | cutting controlled by PLC |

| 17 | Accuracy of cutting | +/- 1mm |

| 18 | Razor blades material | Cr12, quenching 58-62 ° |

| 19 | Electrically controlled system | entire machine controlled by PLC |

| 20 | PLC | DELTA(TAIWAN) |

| 21 | Weight of main forming machine | About 3.2 T |

Working flow:

Our service:

1.Technology :We have technical centers and innovative designing teams for

different kinds of production lines.

2.After Sale Service :Warranty period 1 year , after this period , we are willing to give

help if customer needs accessory . The real cooperation will not

end at the delivery . we believe that satisfied after sale service

means a lot.

3.Inspected by the Sellers :After completing the manufacturing and assembling of the

equipments, we will test the machines and commissioning in the

workshop.

4.Inspected by the Buyers: After confirmation of a sound work of the line, we will invite our

customer to send their representatives to inspect the production

lines in our factories.

Packing and Loading:

Standard Export Packing.

1.One 40ft container for loading one set machine with manual

decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam

film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Machine photos:

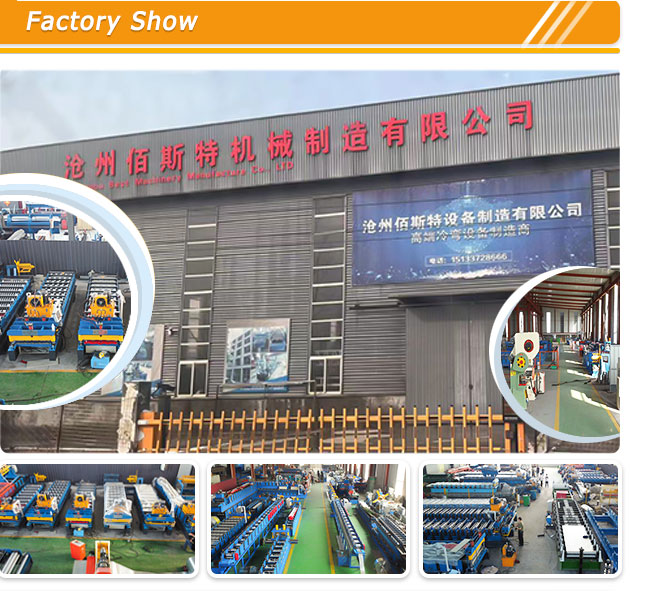

company:

Cangzhou Best Machinery Manufacturing co., LTD is specialized in the manufacture of high-end equipment cold bending forming equipment manufacturer,has a professional engineer for technical guidance.Engineers engaged in cold bending mechanical equipment design for more than 20 years,has a wealth of design concept.Can provide users with a special type of design and manufacture.At the same time to sell equipment for installation,guidance,production,commissioning one-stop service.

Contact me:

If you need more details, please inquiry me, will send you lowest price and machine video.

Cangzhou Best Machinery Co., Ltd

Cangzhou Best Machinery Co., Ltd set up in 2015, with great power in production and techniques, we are a leading manufacturer of roll forming machines in North of China.We have two workshops more than 4000 square meters, and have own processing machines and design engineer, so that can control machine production time and quality;Our factory is near Beijing or Tianjing, and in Cangzhou there is railway station, so it is convinent transport.Welcome to visit our factory anytime.

Our main products are CUSTOMIZED ROLL FORMING MACHINES, because

clients will use roll forming machines instead of bending machine

or pressing machines to save labor, and improve production, our

regular products are roof sheet roll forming machine, roof tile

roll forming machine, CZ roll forming machine, floor decking roll

forming machine, highway guardrail roll forming machine, cable tray

roll forming machine, stud and track roll forming machine, door

roll forming machine, slitting and cut to length, sandwich panel

machine and so on.

We have advanced production equipment and our engineering personnel

and technicians have extensive experience in designing, developing,

and manufacturing machineries. They pay close attention to and keep

up with the developing trend of technologies and use new

technologies in manufacturing machinery, to keep them competitive.

Our products feature high efficiency, high flexibility and low

cost.

"Customers are the first, success comes from development" is our

principle. We bear this in mind during the whole process from

design and development of product to after-sales services. We will

design and manufacture machinery strictly in accordance with your

requirements.

With good after-sales service network, we can provide support

covering the whole process of purchasing, which help you get

perfect machinery. We'll solve all the problems you have while

using the machines and we'll provide considerate services.

Our machines have been sold to North America, like US, Canada, South America, Nicaragua, Peru, Brazil, Bolivia, Uruaguy, Argentina, Europe, like Greece, Middle east, like Saudi Arab, Dubai, Iran, Iraq, Africa, Egypt, Ghana, Nigeria, Ethiopia, Malawi, Kenya, Tanzania, Zambia, Zimbabwe, South Africa, Australia, New Calidonia, Asia, India, Thailand, Philippines, Indonesia, Papua New Guinea,

Bangladesh, Pakistan, Turkmenistan, Malaysia, Vietnam, Mongolia, helping us enter the

international market.

Excellent service and high technology assist you to create a bright

future.

To make sure machine quality, we applied CE certificate and SGS

certificate and so on.

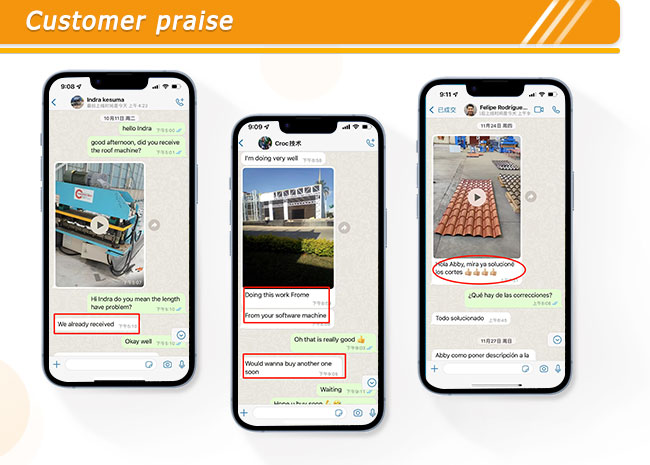

Our roll froming machine exported all over the world and win good repution,clients give good feedback,we have been exported to more than 120 countries and regions in the world, including: Germany, Japan, Italy, Russia, Japan, South Korea, Turkey, Brazil , India, the United Arab Emirates, Saudi Arabia and other countries, the products are subject to a great welcome and praise. INDIA, AFRICA, SOUTH AMERICA.

WE WILL YOUR BEST SUPPLIER IN CHINA,WELCOME TO CONTACT US.