686 & 762 IBR and Corrugated Profile Roll Forming Machine / Metal Roofing Equipment

686 & 762 IBR and Corrugated Africa Pouplar Profile Roll

Forming Machine

Machine components list:

| Name | NO. | Unit |

| 1.De-coiler | 2 | set |

| 2.Forming machine | 1 | set |

| 3.Cutting device | 1 | set |

| 4.PLC control box | 1 | set |

| 5.Hydraulic pump station | 1 | set |

| 6.Production support table | 1 | set |

Main Parameter

1) Material of the profile: GI or color steel

2) Thickness range: 0.3-0.8mm

3) Main motor power:5.5kw, AC motor, motor inside of main machine

(Brand: Guomao of China) (according the final design)

4) Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

5) Roll station: about 18 stations (according the final design)

6) Roller material:ASTM1045 chrome plated surface with chrome,CNC,

7) Shaft diameter: ¢70mm material: SAE1045 with quenching and

tempering

8) Machine roll forming speed:not less than 15m/min

9) Transmission: by chain, one inch, single line

10) Roll former has leveling bolts in the base for adjust the

leveling

11) Machine base frame adopt H beam welding steel

12) In the main roll forming machine have 2 buttons for urgency

stop if happen any malfunction.

13) Machine adopt new station to make machine more strong

14) To avoid accidents,all of drive part adopt protect cover

15) Color of machine: Blue and yellow (or base on customer request)

Detail Information:

1. DECOILER

(1) Max. Width: 1250 mm

(2) Inner Diameter: Φ450 – Φ550 mm

(3) Out Diameter: 1500 mm

(4) Max. Loading Capacity: 5000 kgs

2. ROLL FORMING MACHINE

Rollers: design by senior engineers with Auto-cad software,

manufactured with 45# high grade steel by CNC machine tools and

coated with hard chrome;

Shaft: manufactured with 45# high grade steel by CNC machine tools;

Supporting frame: steel wallboard to guide the forming station

bearing basement;

(1) Material Thickness: 0.3-0.8 mm PPGI and GI

(2) NO. of roller Stations:up 18groups

Down11groups

(3) Material for Rollers: high grade 45# steel polished and coated

with chrome HRC55-60°

(4) Material for shaft: high grade 45# steel polished and coated

with chrome HRC55-60°

(5) Diameter of shaft: 70mm

(6) Frame panel thickness:14mm

(7) Bottom frame: 36# H-section steel

3. CUT-OFF DEVICE

Function: cutting action is controlled by PLC. The main machine

automatically stops and the cutting will take place. After the

cutting, the main machine will automatically start.

Power supply: hydraulic station;

Frame: welding steel frame;

Stroke switch: non-contact photoelectric switch;

Cutting after forming: cut the sheet after roll forming to required

length;

Length measuring: automatic length measuring.

(1)Material for Cut-Off Modular:Cr12 steel after treatment

(2)Hardness for Heat Treatment:HRC55 – 60°

(3)Cut-Off Type: Hydraulic, Automatic Cut-Off

(4) Motor for Hydraulic Stand: 3kW

4.PLC CONTROL BOX

(1) Type: PLC Frequency Control System with touch screen

(2) PLC Brand: Delta

(3) Encoder Brand: Omron

(4)Length Error: ±2mm

(5)Language: English and Chinese

(6)Voltage: 380v/50HZ, 3Phase (it depends on customer requirement)

Electric control system

Automatic length measurement: one unit tooling of length measuring

which is lightly pressed on the surface of the steel sheet; the

tolling will roll with the moving speed of the steel sheet and then

sense to measure its length; length inaccuracy can be amended

easily.

Automatic quantity measurement;

PLC is used to control length & quantity. Machine will

automatically cut to length and stop when required quantity is

achieved;

Control panel: Button-type switch, LED display length and quantity

;

Unit of length: millimeter;

Motor Over-Load, System Over-Current, Short circuit Protection

function;

Display total length and total quantity produced.

Customer inspected machine

Loading Photos

Package:

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

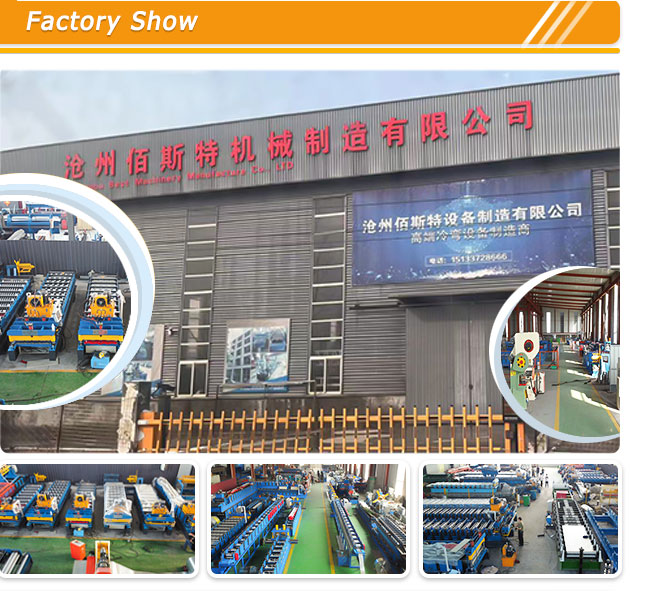

Cangzhou Best Machinery Co., Ltd

Cangzhou Best Machinery Co., Ltd set up in 2015, with great power in production and techniques, we are a leading manufacturer of roll forming machines in North of China.We have two workshops more than 4000 square meters, and have own processing machines and design engineer, so that can control machine production time and quality;Our factory is near Beijing or Tianjing, and in Cangzhou there is railway station, so it is convinent transport.Welcome to visit our factory anytime.

Our main products are CUSTOMIZED ROLL FORMING MACHINES, because

clients will use roll forming machines instead of bending machine

or pressing machines to save labor, and improve production, our

regular products are roof sheet roll forming machine, roof tile

roll forming machine, CZ roll forming machine, floor decking roll

forming machine, highway guardrail roll forming machine, cable tray

roll forming machine, stud and track roll forming machine, door

roll forming machine, slitting and cut to length, sandwich panel

machine and so on.

We have advanced production equipment and our engineering personnel

and technicians have extensive experience in designing, developing,

and manufacturing machineries. They pay close attention to and keep

up with the developing trend of technologies and use new

technologies in manufacturing machinery, to keep them competitive.

Our products feature high efficiency, high flexibility and low

cost.

"Customers are the first, success comes from development" is our

principle. We bear this in mind during the whole process from

design and development of product to after-sales services. We will

design and manufacture machinery strictly in accordance with your

requirements.

With good after-sales service network, we can provide support

covering the whole process of purchasing, which help you get

perfect machinery. We'll solve all the problems you have while

using the machines and we'll provide considerate services.

Our machines have been sold to North America, like US, Canada, South America, Nicaragua, Peru, Brazil, Bolivia, Uruaguy, Argentina, Europe, like Greece, Middle east, like Saudi Arab, Dubai, Iran, Iraq, Africa, Egypt, Ghana, Nigeria, Ethiopia, Malawi, Kenya, Tanzania, Zambia, Zimbabwe, South Africa, Australia, New Calidonia, Asia, India, Thailand, Philippines, Indonesia, Papua New Guinea,

Bangladesh, Pakistan, Turkmenistan, Malaysia, Vietnam, Mongolia, helping us enter the

international market.

Excellent service and high technology assist you to create a bright

future.

To make sure machine quality, we applied CE certificate and SGS

certificate and so on.

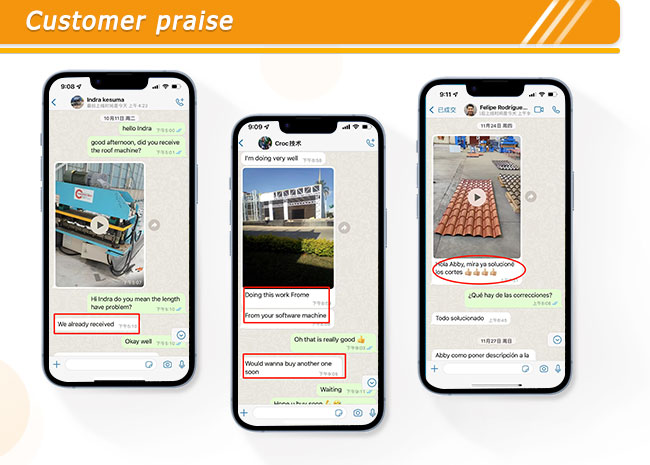

Our roll froming machine exported all over the world and win good repution,clients give good feedback,we have been exported to more than 120 countries and regions in the world, including: Germany, Japan, Italy, Russia, Japan, South Korea, Turkey, Brazil , India, the United Arab Emirates, Saudi Arabia and other countries, the products are subject to a great welcome and praise. INDIA, AFRICA, SOUTH AMERICA.

WE WILL YOUR BEST SUPPLIER IN CHINA,WELCOME TO CONTACT US.