Rain Gutter Roll Forming Machine Construction Material Roofing 450mm - 550mm Inner Diameter

Rain Gutter Roll Forming Machine Construction Material Roofing

Application

The roll formed product is mor durable than the tranditional ppc

pipe, and not easy to aging.

It will make the project more integrate, and help enhancing the

image of all project.

Drainpipe bending machine used for bend the roll formed pipe, to

connect the drainpipe and the elbowed pipe.

Parameter

1. Material:

1) Coil Width: 1000mm

2) Suitable Coil Thickness: 0.3-0.7mm

3) Suitable Raw Material: Galvanized steel sheet

2. The Chart of Process flow

Manual de-coiler --- Electric Feeding --- Servo motor feeding ----oll Forming Machine------Computer Control Cabinet---Automatic cutting Mechanism ---Run-out Tables

3. The equipment including

| Roll forming machine | 1 set |

| Hydraulic cutter | 1 set |

| Electrical control system | 1 set |

| Hydraulic system | 1 set |

| Normal run out table | 3 PC 1m*1m |

| Manual de-coiler | 1 set Max. loading 5 T |

4. Technical specification and details

(1) Hydraulic Ue-coiler

Un-power: manual de-coiler; Max. Capacity: 7T

Suit for coil inner diameter: 508mm, suitable coil Max. out diameter: 1000mm

Manual power expands the coil inner surface.

The de-coiler for reference:

(2) Roll forming machine

| Description | ||

| Machine Size | 6500*1500*1200mm | |

| Machine Weight | About 4.2 T | |

| Frame Materials | 300H steel | |

| Plate thickness | 16mm | |

| Forming Shaft | Diameter | 75mm |

| Material | 40r quenched and tempered material | |

| Forming roller | Cr12 | |

| Cutting System | Hydraulic Cutting, CR12 die steel | |

| Drive mode | 1 inch chain, High temperature quenching | |

| Main Engine power | 5.5 KW with cycloidal reducer | |

| Pump Station Motor | 4KW | |

| Forming Rows | Upper-16 rows Down-13 rows | |

| Forming Speed | 8-12m/min (Variable frequency adjustable speed) | |

| Pressing Thickness | 0.3-0.8mm | |

| Electric Control System | "Delixi" or "CHINT" | |

| Transducer | SIEMENS | |

| Coder | OMRON" | |

| Switch | " CHINT "or" delixi" | |

PLC control system

Usage: control the beginning and the ending of the main part, also

can control the number, length, and the speed of the products.

Adopted PLC , frequency converter , Delta touch screen are from

Taiwan to ensure the high speed with the stability, precision and

the lifetime.

Other electric element are Panasonic.

The receiving table

Usage: to receive the finished product, and transmit it to the

destination.

Varieties of receiving tables, general, better, best,you can

choose. Generally the one is 3 meters, and totally we will offer

two for customers. We also can offer according to the requests from

customers.

Decoiler system

Usage: It is used to support the steel coil and uncoil it in a

turnable way.

Passive uncoil pulled by roll forming system

Loading capacity: 3T

Uncoiling width: 500mm

Inner diameter: 450-550mm

Hydrulic station

It is controlled by gear pump. After filling the hydraulic oil into

the hydraulic oil tank ,the pump drive the cutter machine to begin

the cutting job.

Power: 5.5kw

Hydraulic oil: 46#

Components: The system includes a set of hydraulic tank , a set of

hydraulic oil pump, four hydraulic pipes and two sets of

electromagnetism valves.

Re-sale Service :

1. Send you invitation letter, if you want to visit our factory and

check the machines.

2. Good Quality + Competitive price + Quick Response + Reliable

Service.

Selling Service :

1. Email the production schedule and make prompt delivery.

2. Count the cheapest shipping cost, look for the fastest forwarder

and send relevant documents promptly.

3. Be here for your service at any time.

After-sale Service :

Any questions, contact us by WhatsApp or Telephone.

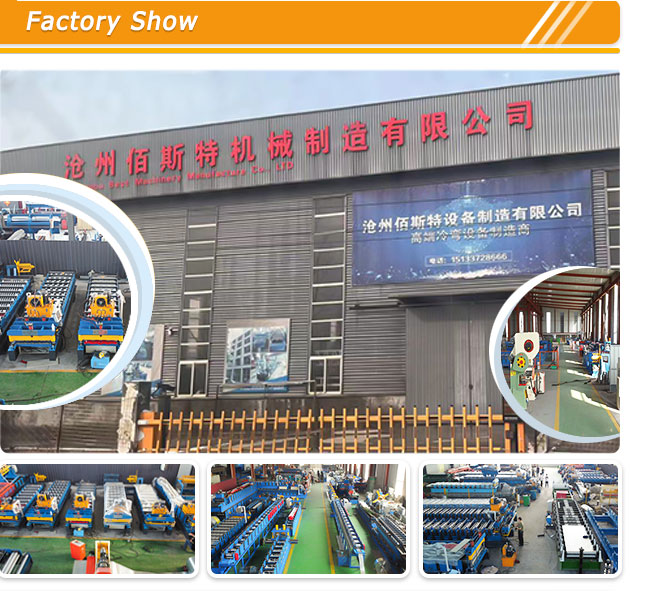

Cangzhou Best Machinery Co., Ltd

Cangzhou Best Machinery Co., Ltd set up in 2015, with great power in production and techniques, we are a leading manufacturer of roll forming machines in North of China.We have two workshops more than 4000 square meters, and have own processing machines and design engineer, so that can control machine production time and quality;Our factory is near Beijing or Tianjing, and in Cangzhou there is railway station, so it is convinent transport.Welcome to visit our factory anytime.

Our main products are CUSTOMIZED ROLL FORMING MACHINES, because

clients will use roll forming machines instead of bending machine

or pressing machines to save labor, and improve production, our

regular products are roof sheet roll forming machine, roof tile

roll forming machine, CZ roll forming machine, floor decking roll

forming machine, highway guardrail roll forming machine, cable tray

roll forming machine, stud and track roll forming machine, door

roll forming machine, slitting and cut to length, sandwich panel

machine and so on.

We have advanced production equipment and our engineering personnel

and technicians have extensive experience in designing, developing,

and manufacturing machineries. They pay close attention to and keep

up with the developing trend of technologies and use new

technologies in manufacturing machinery, to keep them competitive.

Our products feature high efficiency, high flexibility and low

cost.

"Customers are the first, success comes from development" is our

principle. We bear this in mind during the whole process from

design and development of product to after-sales services. We will

design and manufacture machinery strictly in accordance with your

requirements.

With good after-sales service network, we can provide support

covering the whole process of purchasing, which help you get

perfect machinery. We'll solve all the problems you have while

using the machines and we'll provide considerate services.

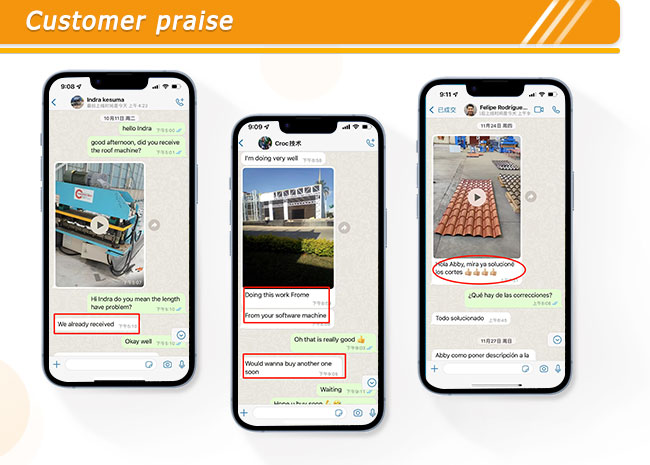

Our machines have been sold to North America, like US, Canada, South America, Nicaragua, Peru, Brazil, Bolivia, Uruaguy, Argentina, Europe, like Greece, Middle east, like Saudi Arab, Dubai, Iran, Iraq, Africa, Egypt, Ghana, Nigeria, Ethiopia, Malawi, Kenya, Tanzania, Zambia, Zimbabwe, South Africa, Australia, New Calidonia, Asia, India, Thailand, Philippines, Indonesia, Papua New Guinea,

Bangladesh, Pakistan, Turkmenistan, Malaysia, Vietnam, Mongolia, helping us enter the

international market.

Excellent service and high technology assist you to create a bright

future.

To make sure machine quality, we applied CE certificate and SGS

certificate and so on.

Our roll froming machine exported all over the world and win good repution,clients give good feedback,we have been exported to more than 120 countries and regions in the world, including: Germany, Japan, Italy, Russia, Japan, South Korea, Turkey, Brazil , India, the United Arab Emirates, Saudi Arabia and other countries, the products are subject to a great welcome and praise. INDIA, AFRICA, SOUTH AMERICA.

WE WILL YOUR BEST SUPPLIER IN CHINA,WELCOME TO CONTACT US.