Wall EPS / PU Sandwich Panel Production Line Precast Auto Cutting

Wall EPS / PU Sandwich Panel Production Line Precast Auto Cutting

Introduction of Continuous Sandwich Panel Production Line

Continuous Sandwich Panel Production Line. It has shorted the trail

production cycle ,improved the productivity by about 20—30%,and

reduced the waste rate .We not only supply advanced facility ,but

offer entire panel production technology .For the service

requirements that during fixing ,debugging ,trail producing and

using process ,we will offer technology suggestion and professional

solution on time.

Advantages of Continuous Sandwich Panel Production Line

Firstly, we have more than 20 years PU sandwich panel experiences,

master a full set of production technology, meanwhile we are top

three on term of PU sandwich panel in china.

Secondly, we not only provide customer production line but also

provide a complete solution for PU sandwich panel technology.

Recovering customer's initial investment with the least raw

materials.

Third, our company be mainly aimed at high and middle grade market,

the quality of raw material we use is higher than normal seen.

Fourth, where the rotation axis between holes, are equipped with

self-lubrication properties of materials bush for improving self

lubrication of parts and prolong its life.

Working flow

Down side rigid board feed----Rolling rack----glue drop onto rigid

board----glue sweep----EPS sheet load----- Rolling rack and

lamination-----glue drop onto EPS Sheet----glue sweep----up rigid

board feed ---Rolling lamination----finished product

Machine components

| No. | Name | Qty |

| 1. | De-coiler | 1 Set |

| 2. | Roll Forming Machine | 1 Set |

| 3. | Laminating Machine | 1 Set |

| 4. | PLC Control Box | 1 Set |

| 5. | Hydraulic Pump | 1 Set |

| 6. | Output table | 1 Set |

| 7. | Saw cutting device | 1 Set |

Parameter

| 1 | Name | EPS Sandwich Panels Machinery |

| 2 | panle profile | 960mm,970mm or 980mm |

| 3 | Coil material | EPS or Rockwool |

| 4 | Thickness of the plate | 0.27-0.8mm |

| 5 | Core thickness | 30-300mm |

| 6 | Production capacity | 4-4.5m/min (the fastest) ,2-2.5m/min(the slowest) |

| 7 | Total power | about 28KW |

| 8 | Weight | 20 ton,two 40-foot HQ |

| 9 | control system | PLC control system, easy to operate, high precision and work stably. |

| 10 | Dimensions of whole production line | about Length34000mm × Width2500mm × Height2500mm |

Re-sale Service :

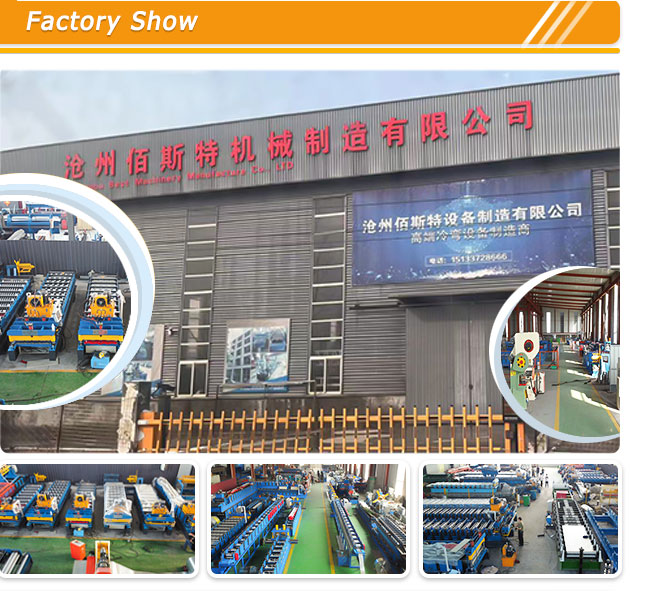

1. Send you invitation letter, if you want to visit our factory and

check the machines.

2. Good Quality + Competitive price + Quick Response + Reliable

Service.

Selling Service :

1. Email the production schedule and make prompt delivery.

2. Count the cheapest shipping cost, look for the fastest forwarder

and send relevant documents promptly.

3. Be here for your service at any time.

After-sale Service :

Any questions, contact us by WhatsApp or Telephone.

Machine Photos