Stainless Steel Rubber Xenon Accelerated Aging Chamber Weathering Test Chamber

Stainless Steel Rubber Accelerated Aging Chamber Weathering Test Chamber

Xenon Aging Test Chamber - Air cooled.pdf

Production Introduction

PID Enviroment Ac380v , Three Phase Five Wire , 10kw Xenon Arc

Aging Test Chamber is used for the examination of the ultraviolet

irradiation resistance capacity when the materials/products are

exposed in ultraviolet irradiation environment. Ultraviolet light

is a term used to describe electromagnetic radiation with

ultraviolet waves shorter than light visible to humans.UV light is

present in sunlight and can cause chemical reactions in certain

materials. This reaction caused them to glow,which is called

fluoresce. It is widely applied to coating ink, paint, resin,

plastics, printing, packaging, aluminum profile,cement, automobile,

motorcycle, cosmetics, metal, electronic, electroplating, medicine,

etc.

Feature

(1) Condensation device simulates the effect of humidity of

outdoor, meeting 100% humidity.

(2) Electronic-eye irradiance control system.

(3) Use blackboard temperature sensor providing precise temperature

and recurring test result.

(4) Perform humidifying, condensation and water spraying

circulating test.

(5) Irradiance is calibrated by CR-10 calibrator and automatic

calibration procedure (Paten technology)

(6) Specimen size and quantity: 75mm×300mm 24pcs, 75mm×150mm 40pcs

Specification

1. Inner chamber and exterior chamber material: SUS304 stainless

steel.

2. Heating: Electrical heater with rapid temperature rise and

temperature distribution

3. RS232 communication interface

4. Power leakage circuit breaker control circuit, overload short

circuit alarm, over-temperature alarm water shortage protection.

| Model | HD-E711 |

| Inner Box Size (DWH) | 950950900mm |

| Outside Dimension (DWH) | 130015001900mm |

| Humiture Range | (RT+10)~70C; 30~98%RH |

| Humiture uniformity | 2C; 3%RH |

| Rainfall time | 1~9999min, adjustable |

| Rainfall cycle | 1~240min, interval is adjustable |

| Xenon lamp light | xenon long-arc lamp, 6KW10%, 290-800nm, 1000W/m2200 |

| Heating/humidifying power | 2.0KW/2.0KW |

| Sample spinning machine speed | 1~5r/ min (adjustable) |

| Sample and xenon lamp distance | 300~375mm |

| Box material | Stainless Steel SUS304# |

| Insulation materials | Superfine heat insulation cotton |

| Insulation body | Superfine glass fabric |

| Circulation system | Single cycle, centrifugal fan |

| Control system | Germany KLOCKNER-MOELLER progammable controler |

| Gas processing | dischager for fector and harmful gas |

Feature

1, Ventilation system: Automatic controlled by temperature controller, and inner chamber cooled by refrigerating system

2, Back panel thermometer: adopt wired transmission technology, which highly improve the control accuracy.

3, Temperature sensor: PT100 platinum resistance temperature body.

4, Equip with intelligent temperature and humidity controller, with PID adjustment and rapid self-turning. It can set several parameters to do cyclic test, directly digital temperature display for easy reading.

5, Multiple protective devices: Over temperature protection, water leakage alarm, over pressure of compressor, electricity leakage protection, alarm and auto power offer protection. In order to protect Xenon light, the light will turn off automatically once open the door.

Hai Da Labtester

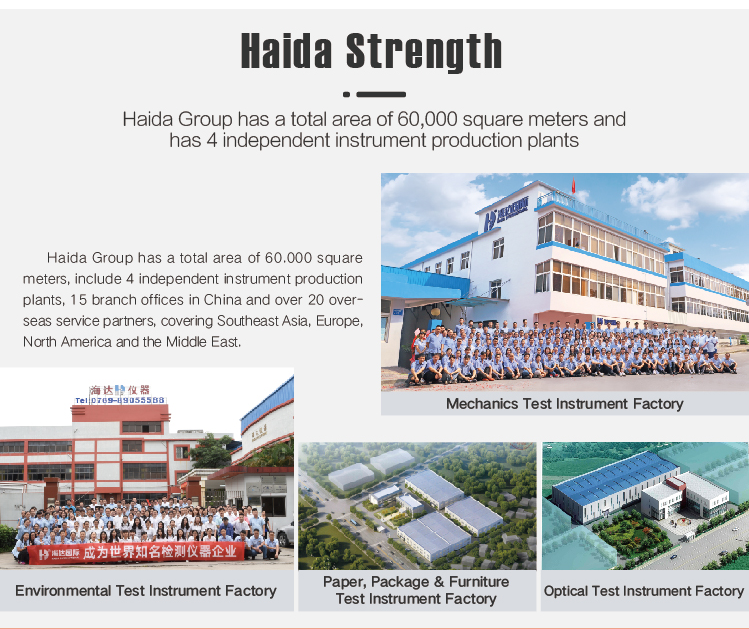

Haida International Equipment Co., Ltd Company Profile

Haida established in 2004 in Dongguan City, where is the “silicon valley” of world manufacturing industry. It is a certified national high-tech enterprise engaged in design, research and development, production, sales, calibration and after-sale service of test equipment, such as paper&packaging test equipment, Furniture test equipment, material mechanics test equipment, optical measurement equipment, environmental reliability testing equipment etc. With the persistent efforts of all staff, Haida owned 4 factories with total 60,000 square meters, 15 branch offices covers South China, North China, East China, Central China and Northwest China, as well over 20 overseas after-sales service sites covers Southeast Asia, Europe, North America and the Middle East with over 28,000 customers.

Haida main business scope includes equipment production, non-standard equipment customization, software development, measurement and maintenance consulting services. The company has passed ISO9000 certification and multiple certifications by internationally renowned testing organizations such as BV, SGS, TUV, and its products comply with GB, ISO, ASTM, EN, JIS, TAPPI, ISTA, DIN, BS and other domestic and foreign standards. Meanwhile, invested a large amount of research and development funds to adhere to the product concept of R & D , sales and products reserve to walk at the forefront of the industry. Moreover Haida participated in composing of furniture test standards and commonly drew up CY/T229-2020 industry standards with the National quality inspection, jointly developed industry test equipment with the National Paper Products Center and Dongguan Quality Testing Furniture Laboratory, co-built the reliability laboratory with many well-known enterprises, and Jointly built the dangerous articles packaging laboratory with Guangdong Huangpu Customs Technology Center.

Haida adheres to the vision of "To be the World Class Testing Equipment enterprise" and attaches importance to platform construction and talent reserves. Having 630 employee which contain 150 technicians and more than 300 bachelors, 5 Masters, and 3 PhDs. Haida have won 2 national invention patents and over 100 utility model patents, At the same time, established 5 industry-university-research cooperation bases with universities and research institutes and invited more than 20 doctoral supervisors as consultants.

Looking forward to the future, Haida will fulfill the mission of "Deliver the best testing equipment to our customers" and adhere to the core values of "Creative, Efficiency, Inheritance, Passion and Persistence". Taking a green, low-carbon, and environmentally friendly sustainable development path, Haida will continuously optimize the product structure to realize the transformation and upgrade of the enterprise itself. It is the eternal pursuit of Haida people to build Haida into a comprehensive provider of testing equipment with advanced technology, excellent quality, high-quality service, and win-win cooperation!

Haida Headquarter

Haida Facyory

Haida Team