Digital Display Hydraulic Universal Testing Machine High Accurate Load Cell

Digital Display Hydraulic Universal Testing Machine High Accurate Load Cell

![]() HD-B611-S Universal Test Machine.pdf

HD-B611-S Universal Test Machine.pdf

![]() HD-B616-1 30T Hydraulic Universal Test Machine.pdf...

HD-B616-1 30T Hydraulic Universal Test Machine.pdf...

![]() HD-B616-2 60T Hydraulic Universal Test Machine.pdf...

HD-B616-2 60T Hydraulic Universal Test Machine.pdf...

![]() HD-B616-3 100T Hydraulic Universal Test Machine.pd...

HD-B616-3 100T Hydraulic Universal Test Machine.pd...

![]() HD-B616-4 200T Hydraulic Universal Test Machine.pd...

HD-B616-4 200T Hydraulic Universal Test Machine.pd...

1. instroduction

Universal Material Hydraulic Tensile Testing Machine With High

Accurate Load Cell is designed of electro-hydraulic digital display and manual

hydraulic loading system, main engine controller separately fixed.

It has the characteristics of operation amenity, working steady,

high accuracy and loading steady. It can implement the

experimentations such as the tensile, compression, bending, cutting

etc. to the metal, nonmetallic composite materials.

2. structure

The main engine consists of an adjustable support (base, screw

thread pole, moveable crossbeam (lower clamp set)) and a working

frame (working oil tank, piston, platform, support crossbeam (upper

clamp set)). Element of the machine: high-pressure oil pump supply

oil to the working oil tank, the piston moves and press board and

upper crossbeam to do stretch and press test. The stretch test is

done in the space between upper crossbeam and movable crossbeam.

The life motor, gear, chain drive rotate at a same speed to move

the crossbeam.

3. characteristics

Universal Material Hydraulic Tensile Testing Machine With High

Accurate Load Cell has advantages such as high precision, light weight, easy

operation, clamping automatic hydraulic pressure, long use life and

so on. It is applicable for detecting various indexes such as

tension, compression resistance, bending etc. to metal and

non-metallic material in various laboratories.

Main specifications

Model: | HD-B616 |

Max. Test load: | 60T |

Relative error of indicate value of load : | ±1% |

Max. Ram stroke: | 250mm |

Max. Tensile space: | 800mm(including piston stroke) |

Max. Compression space: | 700mm(including piston stroke) |

Display: | Computer control and display |

Tensile grips for round specimen : | φ6-φ26mm |

Tensile grips for flat specimen: | 0-15mm |

Distance for two columns: | 500mm |

Upper and lower platen size: | 200x200mm |

The span of bending: | 450mm |

Width of bending roller: | 140mm |

Dia. of bending roller: | 30mm |

Clamping mode: | Hydraulically |

Transducer: | load cell |

Deformation measuring: | YYU–10/50 |

Dimensions of load frame : | 990×600×2435mm |

Dimension of controller : | 1140×700×930mm |

All weight: | 2800kg |

Main standard accessories

Upper and lower platen for compression(200x200mm) | 1 set |

Extensometer | 1 set |

Round specimen grip for tensile ( φ6-φ26mm ) | 1 set |

Flat specimen grip for tensile ( 0-15mm ) | 1 set |

Bending accessories | 1 set |

High accurate load cell | 1 set |

High precision photoelectric encoder Measuring the displacement | 1 set |

High pressure pump | 1 set |

Proportion Valve | 1 set |

Electro-hydraulic servo valve | 1 set |

Shearing accessories ( Optional accessories) | 1 set |

Specifications

1. it is digtial type

2. it is hydraulic

3. it can do the test of tensile, compression, bending, and so on

1. instroduction

Model WES-300B hydraulic universal testing machine UTM is designed

of electro-hydraulic digital display and manual hydraulic loading

system, main engine controller separately fixed. It has the

characteristics of operation amenity, working steady, high accuracy

and loading steady. It can implement the experimentations such as

the tensile, compression, bending, cutting etc. to the metal,

nonmetallic composite materials.

2. structure

The main engine consists of an adjustable support (base, screw

thread pole, moveable crossbeam (lower clamp set)) and a working

frame (working oil tank, piston, platform, support crossbeam (upper

clamp set)). Element of the machine: high-pressure oil pump supply

oil to the working oil tank, the piston moves and press board and

upper crossbeam to do stretch and press test. The stretch test is

done in the space between upper crossbeam and movable crossbeam.

The life motor, gear, chain drive rotate at a same speed to move

the crossbeam.

3. characteristics

Computer Control And Display Hydraulic Metal Tensile Testing

Machine has advantages such as high precision, light weight, easy

operation, clamping automatic hydraulic pressure, long use life and

so on. It is applicable for detecting various indexes such as

tension, compression resistance, bending etc. to metal and

non-metallic material in various laboratories.

Hai Da Labtester

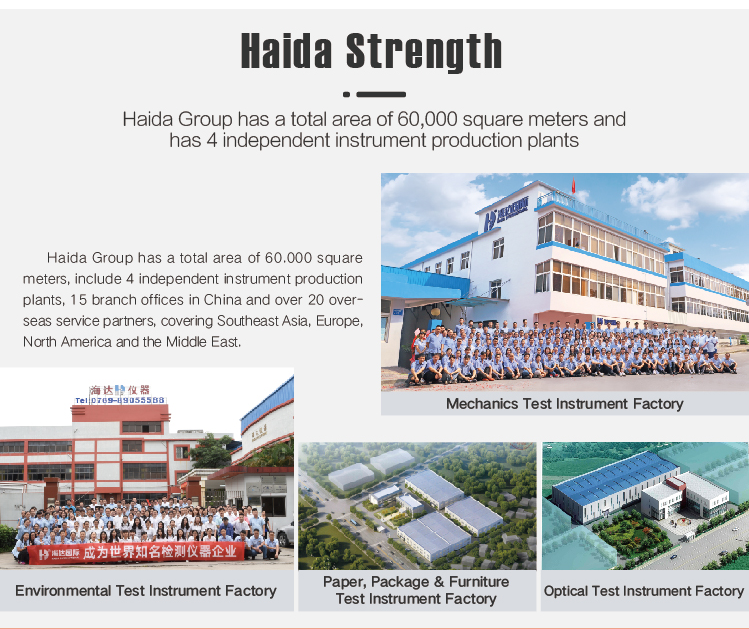

Haida International Equipment Co., Ltd Company Profile

Haida established in 2004 in Dongguan City, where is the “silicon valley” of world manufacturing industry. It is a certified national high-tech enterprise engaged in design, research and development, production, sales, calibration and after-sale service of test equipment, such as paper&packaging test equipment, Furniture test equipment, material mechanics test equipment, optical measurement equipment, environmental reliability testing equipment etc. With the persistent efforts of all staff, Haida owned 4 factories with total 60,000 square meters, 15 branch offices covers South China, North China, East China, Central China and Northwest China, as well over 20 overseas after-sales service sites covers Southeast Asia, Europe, North America and the Middle East with over 28,000 customers.

Haida main business scope includes equipment production, non-standard equipment customization, software development, measurement and maintenance consulting services. The company has passed ISO9000 certification and multiple certifications by internationally renowned testing organizations such as BV, SGS, TUV, and its products comply with GB, ISO, ASTM, EN, JIS, TAPPI, ISTA, DIN, BS and other domestic and foreign standards. Meanwhile, invested a large amount of research and development funds to adhere to the product concept of R & D , sales and products reserve to walk at the forefront of the industry. Moreover Haida participated in composing of furniture test standards and commonly drew up CY/T229-2020 industry standards with the National quality inspection, jointly developed industry test equipment with the National Paper Products Center and Dongguan Quality Testing Furniture Laboratory, co-built the reliability laboratory with many well-known enterprises, and Jointly built the dangerous articles packaging laboratory with Guangdong Huangpu Customs Technology Center.

Haida adheres to the vision of "To be the World Class Testing Equipment enterprise" and attaches importance to platform construction and talent reserves. Having 630 employee which contain 150 technicians and more than 300 bachelors, 5 Masters, and 3 PhDs. Haida have won 2 national invention patents and over 100 utility model patents, At the same time, established 5 industry-university-research cooperation bases with universities and research institutes and invited more than 20 doctoral supervisors as consultants.

Looking forward to the future, Haida will fulfill the mission of "Deliver the best testing equipment to our customers" and adhere to the core values of "Creative, Efficiency, Inheritance, Passion and Persistence". Taking a green, low-carbon, and environmentally friendly sustainable development path, Haida will continuously optimize the product structure to realize the transformation and upgrade of the enterprise itself. It is the eternal pursuit of Haida people to build Haida into a comprehensive provider of testing equipment with advanced technology, excellent quality, high-quality service, and win-win cooperation!

Haida Headquarter

Haida Facyory

Haida Team